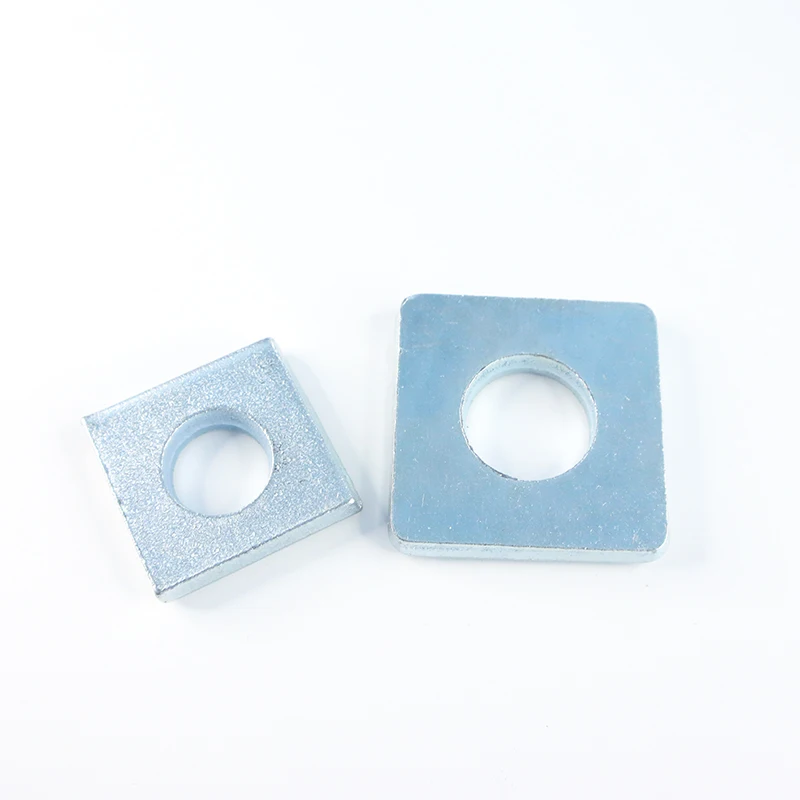

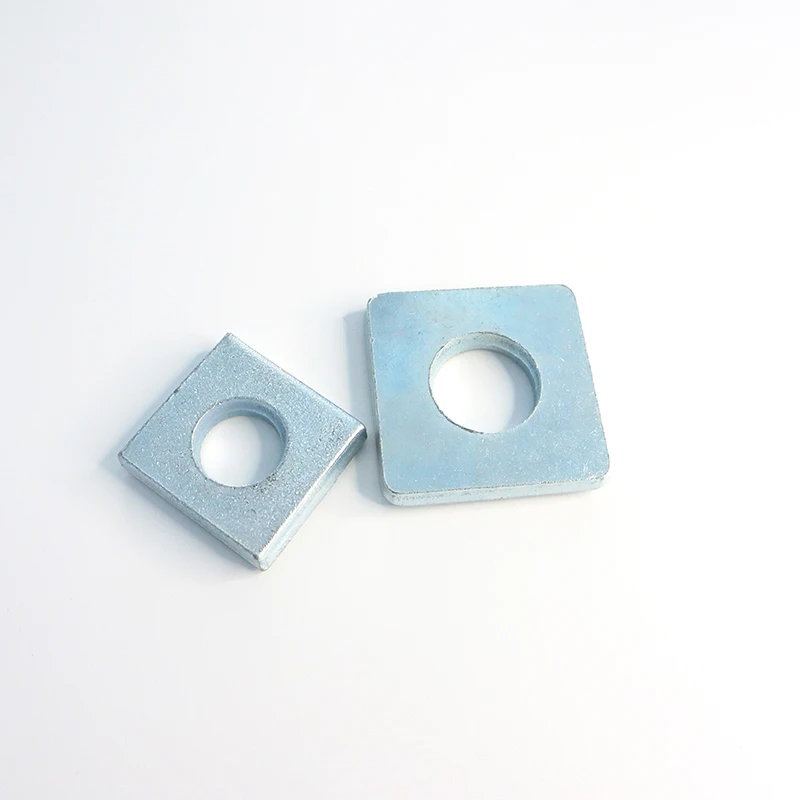

Square Washers are flat, rectangular washers with a central hole, designed to distribute the load of bolts/nuts over a larger surface area while preventing rotational movement in wood, metal, or concrete. Manufactured from carbon steel (zinc-plated), stainless steel (304/316), or galvanized steel, they offer superior grip and stability in high-stress environments compared to round washers.

- Material:

- Carbon Steel: Grade A36 (zinc-plated/black oxide) for general use.

- Stainless Steel: 304 (A2) for corrosion resistance; 316 (A4) for marine/chemical environments.

- Alloy Steel: Heat-treated for heavy-duty applications (e.g., construction machinery).

- Size Range:

- Metric: M6–M100 (side length: 12–200 mm, ISO 7089 adapted).

- Imperial: 1/4"–4" (side length: 1/2"–8", ASME B18.22.1).

- Key Dimensions:

- Side Length (S): 2×–3× bolt diameter (e.g., M8 washer: S = 16 mm).

- Thickness: 2–15 mm (customizable for load requirements).

- Finish: Zinc plating (RoHS/REACH), hot-dip galvanized (HDG), or passivated (stainless steel).

- Standard Carbon Steel/Zinc-Plated (M8–M24): 5,000 pieces (in-stock sizes).

- Stainless Steel (304/316): 2,000 pieces (custom side lengths available).

- Oversized Washers (M36+): 1,000 pieces (industrial-grade).

Factory Advantages: ISO 9001-certified production, precision punching for square edges, and support for non-standard thicknesses or anti-slip finishes with lead times of 10–20 days.

- Construction:

- Wood Framing: Securing beams and posts in timber structures (prevents washer spin in wood).

- Steel Connections: Distributing loads in bolted steel trusses or bridges (HDG-coated for outdoor use).

- Industrial Machinery:

- Heavy Equipment: Anchoring motors, presses, or mining machinery with high-vibration loads.

- Agricultural Tools: Securing plows, harvesters, and trailers in rough terrain.

- Automotive/Marine:

- Truck Axles: High-strength square washers for leaf spring attachments.

- Boat Hardware: 316 stainless steel washers for corrosion-resistant deck fittings.

- DIY Projects:

- Fences/Gates: Preventing nuts from sinking into wooden posts or metal rails.

- Anti-Rotation Design: Square edges grip mating surfaces, reducing the need for lock washers in some applications.

- Load Distribution: Larger surface area reduces pressure by up to 60% compared to round washers (calculated via contact area).

- Corrosion Resistance:

- HDG carbon steel: 1,000+ hours salt spray (ASTM B117).

- 316 stainless steel: 2,000+ hours salt spray for offshore environments.

- High-Torque Compatibility: Thick profiles (up to 15 mm) withstand heavy wrenching without deformation.

- Material Grades: Aluminum (for lightweight), brass (decorative), or spring steel (for elastic deformation).

- Special Coatings: PTFE (low friction), zinc-nickel (military-grade corrosion resistance), or powder coating (custom colors).

- Bespoke Sizes: Non-standard side lengths (e.g., 25 mm for M10 bolts) or chamfered edges for easier installation.

- Cost Efficiency: Eliminates the need for additional anti-rotation components like serrated washers.

- Engineering Support: Free CAD models and load calculation assistance for complex projects.

- Sustainability: Recyclable steel options and energy-efficient manufacturing processes.

Contact Us

Request a quote for square washers tailored to your high-torque needs! Factory-direct pricing and global shipping for construction, industrial, and marine applications.

JH Bolt Co., Ltd is a professional manufacturer of different types of bolts with more than 15 years rich manufacturer experience. The factory area is more than 1500 squares with more than hundreds different types ofnevproduction machines. There are more than 50 people who work here for at least 5 years.With quality &customer frst, staffs second, then company, Our products are widely recog-nized and trusted by users all over the world. Proft for the development of communication, We are here for you 12 hours a day, 7 days a week!