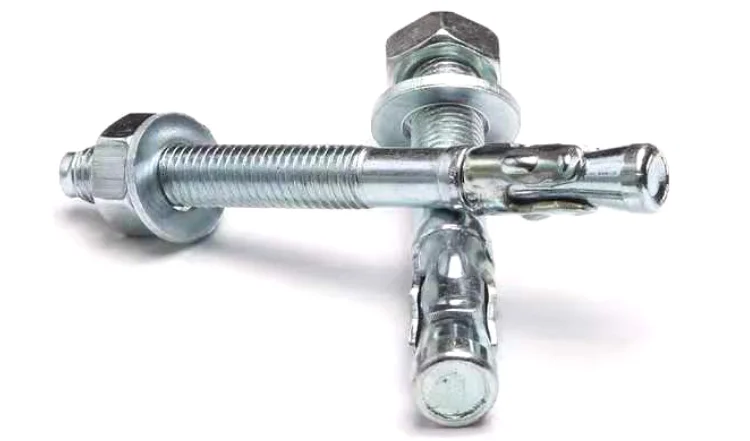

Wedge Anchors are mechanical fasteners designed to secure heavy loads to concrete, brick, or stone by expanding a wedge against the substrate when tightened. Ideal for structural and non-structural applications, they consist of a threaded bolt, expandable sleeve, and nut, providing high tensile and shear strength. Manufactured from carbon steel (zinc-plated), stainless steel (304/316), or alloy steel (Grade B7), they offer durability in harsh environments.

- Material:

- Carbon Steel: Grade 4.8/8.8 (zinc-plated or hot-dip galvanized).

- Stainless Steel: 304 (A2) for general corrosion resistance; 316 (A4) for marine/chemical environments.

- Alloy Steel: ASTM A193 Grade B7 (heat-treated for high-temperature/high-strength use).

- Size Range:

- Diameter: M6–M36 (metric) / 1/4"–1-1/2" (imperial).

- Length: 30–300 mm (embedment depth varies by substrate thickness).

- Design Features:

- Wedge Sleeve: Split design that expands radially when the nut is tightened.

- Threaded Shank: Full or partial threads for compatibility with nuts and washers.

- Head Style: Hex head (standard) or countersunk for flush installations.

- Load Capacity:

- Tensile Strength: 1,000–20,000 kg (depending on size and material).

- Compliance: Meets ANSI/ASME A325.1 (USA) and EN 15048 (Europe) for structural applications.

- Standard Carbon Steel/Zinc-Plated (M10–M20): 5,000 pieces (in-stock sizes).

- Stainless Steel (304/316): 2,000 pieces (custom lengths available).

- Alloy Steel/Heavy-Duty (M24+): 1,000 pieces (project-based orders).

Factory Advantages: ISO 9001-certified production, 100% load testing for critical applications, and support for non-standard embedment depths or corrosion-resistant coatings (e.g., Dacromet) with lead times of 15–30 days.

- Construction: Securing steel columns, machinery bases, and railings to concrete foundations.

- Industrial: Mounting conveyor systems, storage racks, and heavy equipment in factories.

- Infrastructure: Anchoring highway guardrails, bridge components, and traffic signals.

- Marine/Aquatic: Fixing docks, piers, and offshore platforms (316 stainless steel options).

- Expansion Mechanism: Wedge design creates a secure, permanent bond without adhesives.

- Vibration Resistance: Ideal for dynamic loads in machinery or seismic zones.

- Corrosion Protection:

- Hot-dip galvanized (HDG): 1,000+ hours salt spray (ASTM B117).

- 316 stainless steel: 2,000+ hours salt spray for extreme environments.

- Temperature Tolerance: -40°C to +400°C (alloy steel Grade B7 for high-temperature applications).

- Material Upgrades: 2205 duplex stainless steel for ultra-high strength and corrosion resistance.

- Special Coatings: PTFE (anti-seize), zinc-nickel (military-grade), or color-coded finishes.

- Bespoke Sizes: Oversized diameters (M48+), extended shanks, or metric-imperial hybrid threads.

- Engineering Support: Free design calculations and CAD drawings for complex projects.

- Quality Assurance: Material test reports (MTC) and proof load certificates available upon request.

- Sustainability: Recyclable steel options and low-carbon manufacturing processes.

Contact Us

Request a quote for wedge anchors tailored to your load requirements! Factory-direct pricing and global shipping for infrastructure, industrial, and marine projects.

JH Bolt Co., Ltd is a professional manufacturer of different types of bolts with more than 15 years rich manufacturer experience. The factory area is more than 1500 squares with more than hundreds different types ofnevproduction machines. There are more than 50 people who work here for at least 5 years.With quality &customer frst, staffs second, then company, Our products are widely recog-nized and trusted by users all over the world. Proft for the development of communication, We are here for you 12 hours a day, 7 days a week!