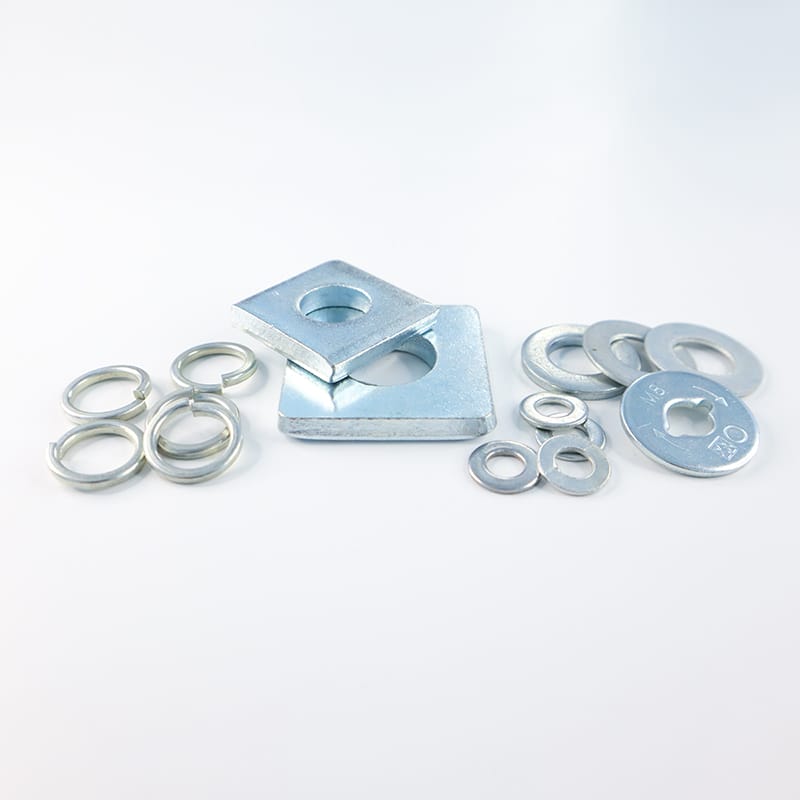

Stainless Steel Spring Washers (also called "elastic washers" or "disc spring washers") are ring-shaped components designed to provide elastic tension and vibration resistance in bolted connections. Made from corrosion-resistant stainless steel (304/316), they prevent loosening caused by mechanical stress, thermal expansion, or dynamic loads, making them ideal for high-moisture, high-temperature, or industrial environments.

- Material:

- 304 Stainless Steel (A2): Standard corrosion resistance, widely used in general applications.

- 316 Stainless Steel (A4): Enhanced resistance to chlorides, acids, and marine environments.

- Size Range:

- Metric: M3–M36 (ISO 7089, GB/T 93)

- Imperial: #4–1-1/2" (UNC/UNF, ASME B18.21.1)

- Design Types:

- Standard Helical Spring Washer: Traditional "split ring" design with a gap for radial expansion.

- Wave Spring Washer: Multi-lobe wave shape for uniform load distribution (lower profile than helical).

- Belleville Washer (Disc Spring): Conical shape for high axial load capacity in compact spaces.

- Key Dimensions:

- Outer Diameter (D): 1.5× to 2× bolt diameter (e.g., M8 washer: OD ≈ 16 mm).

- Thickness (t): 0.8–4 mm, varying by size and load requirement.

- Finish: Passivated (standard for 304/316) or electropolished for enhanced smoothness.

- Standard 304 Spring Washers (M4–M16): 5,000 pieces (in-stock sizes).

- 316 Stainless Steel or Non-Standard Sizes (e.g., M24+): 2,000 pieces (custom orders).

- Belleville Washers: 1,000 pieces (engineered to specification).

Factory Advantages: ISO 9001-certified production, precision stamping for consistent spring force, and support for custom hardness (e.g., 180–210 HV for reduced brittleness) and non-standard geometries.

- Marine/Aquatic Systems: Securing pumps, valves, and hull components in saltwater environments (316 SS).

- Industrial Equipment: Vibrating machinery (e.g., motors, conveyors), where traditional washers fail due to constant motion.

- HVAC/Plumbing: Preventing pipe flange loosening in high-temperature/high-pressure systems.

- Automotive: Engine compartments, exhaust systems, and suspension parts (resists oil, grease, and road salt).

- Anti-Loosening Mechanism:

- Spring tension creates axial force to counteract bolt relaxation.

- Helical washers "bite" into mating surfaces for additional friction.

- Corrosion Resistance:

- 304 SS: 500+ hours salt spray test (ASTM B117).

- 316 SS: 1,000+ hours salt spray test (ideal for coastal or chemical plants).

- Temperature Range: -20°C to +300°C (304) / -60°C to +400°C (316), suitable for extreme environments.

- Material Grades: 430 SS (magnetic) or 2205 duplex SS for ultra-high strength.

- Special Coatings: PTFE (low friction), DLC (diamond-like carbon for wear resistance).

- Bespoke Sizes: Non-standard inner/outer diameters or thicknesses for unique applications.

Contact Us

Request a quote for stainless steel spring washers! Factory-direct supply ensures reliable anti-loosening performance in corrosive, high-vibration, or high-temperature settings. Bulk discounts available for orders over 10,000 pieces.

JH Bolt Co., Ltd is a professional manufacturer of different types of bolts with more than 15 years rich manufacturer experience. The factory area is more than 1500 squares with more than hundreds different types ofnevproduction machines. There are more than 50 people who work here for at least 5 years.With quality &customer frst, staffs second, then company, Our products are widely recog-nized and trusted by users all over the world. Proft for the development of communication, We are here for you 12 hours a day, 7 days a week!