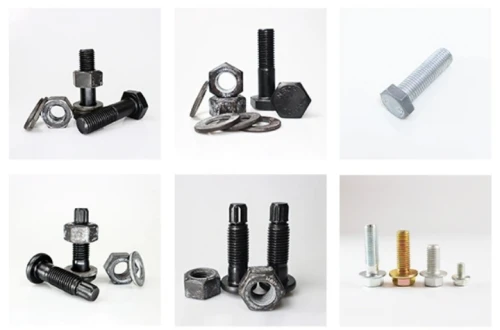

When it comes to trailer wheels, safety, durability, and performance are key. But how do you make sure your trailer wheels are up to the task? The answer lies in the unsung hero of every trailer: the stud bolt. These seemingly small but mighty components hold everything together, ensuring that your wheels stay securely in place, no matter how tough the journey. And when it comes to high-quality stud bolts for trailer wheels, nothing beats the custom-made, factory-direct options that offer fast shipping.

But let’s dive deeper: What makes a stud bolt for trailer wheels so crucial, and why should you choose custom-made bolts for your trailer?

The Role of Stud Bolts in Trailer Wheels

Stud bolts are essential fasteners that attach the wheel hubs to the axles of your trailer. They help ensure that the wheel stays firmly in place, even under the stress of heavy loads, high-speed driving, and rough roads. Without a solid stud bolt, your trailer wheels could wobble or even detach, leading to safety hazards or unnecessary wear.

For trailer wheels, stud bolts need to meet specific demands. They must be:

- Strong enough to handle the weight of the trailer and its cargo.

- Resistant to corrosion from road salt, water, and other harsh elements.

- Durable to withstand the constant vibrations and shocks during travel.

Why Choose Custom-Made Stud Bolts for Your Trailer Wheels?

- Tailored to Your Exact Needs: Custom-made stud bolts allow you to select the perfect size, material, and finish for your trailer. Whether you need longer bolts, stronger steel alloys, or corrosion-resistant coatings, customizing your stud bolts ensures that they meet the unique demands of your trailer’s specifications.

- Perfect Fit: Not all trailers are the same. Using custom stud bolts ensures that your fasteners fit precisely into your wheel hubs, reducing the chances of wear and tear and ensuring that your wheels stay in place for longer periods.

- Enhanced Safety: With high-quality custom stud bolts, you’re investing in the safety of your trailer. A bolt that’s designed specifically for your trailer’s weight and use case ensures a secure attachment to the wheel, preventing wheel detachment and the risks that come with it.

- Made for Heavy Duty: Custom-made stud bolts for trailer wheels are typically made of high-strength steel or alloy metals, which are ideal for heavy-duty applications. These materials ensure that the bolts don’t just meet standard requirements, but are tough enough for long-term and high-stress use.

The Fast Shipping Advantage: Why Wait?

When you need to replace or upgrade the stud bolts on your trailer, waiting for parts can slow you down. Factory-direct suppliers are the solution to this problem. Here’s why:

- Quick Turnaround: Directly sourcing from the factory means fast processing and shorter lead times. No more waiting weeks for delivery! Whether you’re looking for a single replacement bolt or a bulk order for multiple trailers, you’ll get your parts quickly and efficiently.

- Efficient Supply Chain: By eliminating middlemen, you ensure that the stud bolts reach you faster and at a better price. Plus, you won’t have to worry about delays caused by distributors or retailers.

- Reliability: When you order directly from the manufacturer, you know exactly what you’re getting. The bolts are produced to meet industry standards, and you can be confident that the quality and dimensions will be exactly as promised.

Why High-Quality Stud Bolts Are Essential for Trailer Wheels

- Heavy Loads: Trailers carry varying amounts of weight, from light loads to heavy machinery. The stud bolt must be able to withstand the forces exerted by these loads without failing.

- Constant Vibration: Trailers are subjected to constant vibrations during transit. Quality stud bolts prevent loosening or breaking under these conditions, ensuring the wheels remain secure at all times.

- Rust and Corrosion Resistance: Exposure to water, road salt, and other corrosive elements can weaken bolts over time. Custom-made stud bolts with anti-corrosion coatings help ensure that your bolts stand the test of time and don’t fail prematurely.

What to Look for When Choosing Stud Bolts for Trailer Wheels

- Material: The most common materials used for stud bolts are steel, stainless steel, and alloy steels. Make sure the material suits your trailer’s usage, whether you’re hauling light cargo or working in tough conditions.

- Thread Type: Whether you need fine threads or coarse threads, make sure to choose bolts with threads that match your wheel hubs for optimal performance.

- Coating: If your trailer is exposed to harsh weather conditions, look for galvanized or zinc-coated bolts that provide extra resistance against rust and corrosion.

- Size and Length: Ensure that you choose the correct length and diameter of the stud bolts to fit your specific trailer model. Customization allows you to match your exact requirements.

Conclusion: Get Ready to Roll with Custom-Made Stud Bolts

Choosing custom-made stud bolts for your trailer wheels not only guarantees that you’ll get the best fit, strength, and corrosion resistance but also ensures that your wheels stay securely in place, no matter how tough the road ahead is.

So, whether you’re hauling goods across town or transporting heavy equipment across rugged terrains, don’t overlook the importance of these essential fasteners.

Order high-quality stud bolts directly from the factory, and experience the fast shipping, customization options, and reliability that come with sourcing from the source. Your trailer will thank you, and you’ll be rolling with confidence, knowing that your wheels are locked in securely.