Hexagon socket countersunk bolts are an essential type of fastener widely used in various industries, from machinery manufacturing to construction. Their distinct design combines the functionality of a hexagonal socket with a countersunk head, making them ideal for applications where a flush finish is needed. In this article, we will delve into the features, advantages, and uses of hexagon socket countersunk bolts, as well as why they are favored for many precision engineering tasks.

What Are Hexagon Socket Countersunk Bolts?

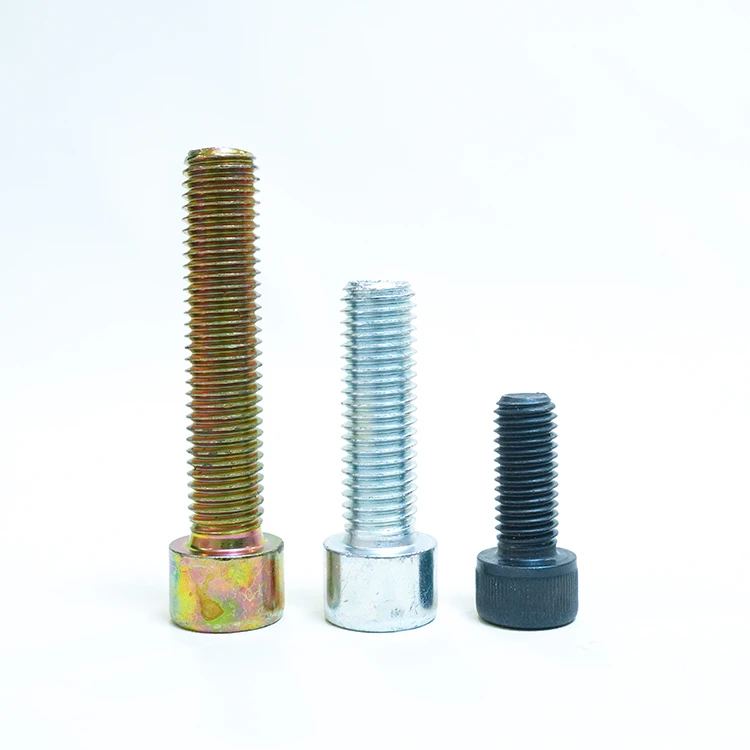

A hexagon socket countersunk bolt is a type of fastener that features a hexagonal socket drive and a countersunk head. The hexagonal drive is designed to be used with an Allen wrench or hex key, allowing for a secure and high-torque connection. The countersunk head, on the other hand, is designed to sit flush with the surface of the material once the bolt is tightened, providing a sleek and smooth finish. This combination of features offers both aesthetic and functional benefits, making it a popular choice in a wide range of applications.

Key Features of Hexagon Socket Countersunk Bolts

- Countersunk Head Design

The main distinguishing feature of these bolts is their countersunk head. The head is tapered, allowing the bolt to sit flush with the surface of the material, which helps eliminate protrusions. This makes them ideal for applications where the surface needs to remain smooth, such as in aerospace, automotive, or furniture applications. - Hexagonal Socket Drive

The hexagonal recess in the bolt head is designed for use with a hex key or Allen wrench. This feature allows for higher torque to be applied compared to other drive types, ensuring a tight, secure fit in applications that demand strength and precision. - Material Strength

These bolts are commonly made from materials such as carbon steel, stainless steel, or alloy steel, ensuring strength, durability, and corrosion resistance. Depending on the material, hexagon socket countersunk bolts can be used in various environmental conditions, including harsh outdoor environments, humid areas, or even underwater applications. - Available in Multiple Sizes

Hexagon socket countersunk bolts are available in a wide range of sizes, from small bolts for delicate machinery to large bolts for heavy-duty structural applications. This size versatility ensures they can be used in a variety of industries and for different types of projects.

Applications of Hexagon Socket Countersunk Bolts

Hexagon socket countersunk bolts are used in numerous industries due to their unique design and benefits. Some of the most common applications include:

- Aerospace Industry

In the aerospace sector, precision and smooth surfaces are critical. Hexagon socket countersunk bolts are frequently used to assemble parts of airplanes, spacecraft, and satellites, ensuring that components fit securely without protruding fasteners that could disrupt aerodynamics or safety. - Automotive Manufacturing

These bolts are essential in automotive assembly, where securing parts such as body panels, engine components, and chassis is important. The countersunk head ensures a smooth finish that doesn’t affect the car’s aerodynamics or appearance, while the hexagonal socket provides the strength needed for high-torque applications. - Electronics and Appliances

In electronic devices and household appliances, hexagon socket countersunk bolts are often used to assemble components that require precise, secure fastening. The flush finish prevents any interference with other parts or wiring, ensuring functionality and safety. - Furniture Assembly

In furniture manufacturing, especially for pieces like desks, cabinets, and shelves, hexagon socket countersunk bolts are used for clean and seamless assembly. Their flush finish ensures that no part of the fastener is visible once installed, giving the furniture a polished and professional look. - Construction and Heavy Machinery

In construction and heavy machinery, these bolts are used in structural components where a smooth finish is required, such as securing metal beams or fastening plates. The strength and durability of the materials used in these bolts ensure that they can handle the high stresses and demands of construction sites.

Advantages of Hexagon Socket Countersunk Bolts

- Flush Finish for Aesthetic and Practical Purposes

The countersunk design of the bolt head allows it to sit flush with the surface of the material, providing a clean and aesthetically pleasing appearance. This makes them ideal for applications where the final product’s appearance is important, such as in automotive or aerospace applications. - Improved Torque and Grip

The hexagonal socket allows for the application of more torque during installation, ensuring a tight and secure connection. This feature is especially important in high-stress or high-vibration applications, where a loose bolt could lead to failures or malfunctions. - Durable and Corrosion-Resistant

Hexagon socket countersunk bolts made from stainless steel or alloy steel are highly resistant to corrosion, making them suitable for use in outdoor environments or in areas exposed to moisture. Their durability ensures long-lasting performance even under harsh conditions. - Easy to Install and Remove

The hexagonal socket provides a firm grip with an Allen wrench, making the bolts easy to install and remove. This is particularly useful in applications where frequent disassembly is required, such as in maintenance or repair work.

Choosing the Right Hexagon Socket Countersunk Bolt

When selecting a hexagon socket countersunk bolt for your application, consider the following factors:

- Material: Depending on the environment where the bolt will be used, choose a material that offers the appropriate level of strength and corrosion resistance. Stainless steel is ideal for outdoor applications, while carbon steel may be more appropriate for general use.

- Size and Length: Ensure that the size of the bolt matches the requirements of your project. The length and diameter should fit the components you are fastening for optimal performance.

- Strength Requirements: For applications that require additional strength, such as heavy machinery or automotive assembly, select bolts made from stronger materials like alloy steel or heat-treated steel.

Conclusion

Hexagon socket countersunk bolts are versatile, strong, and reliable fasteners that provide both aesthetic and functional benefits. Their countersunk design ensures a smooth finish, while the hexagonal socket drive allows for high torque, making them ideal for a variety of applications in industries such as aerospace, automotive, electronics, and construction. By understanding the features and advantages of these bolts, you can make an informed decision about which fastener best suits your needs, ensuring durability and security in your projects.