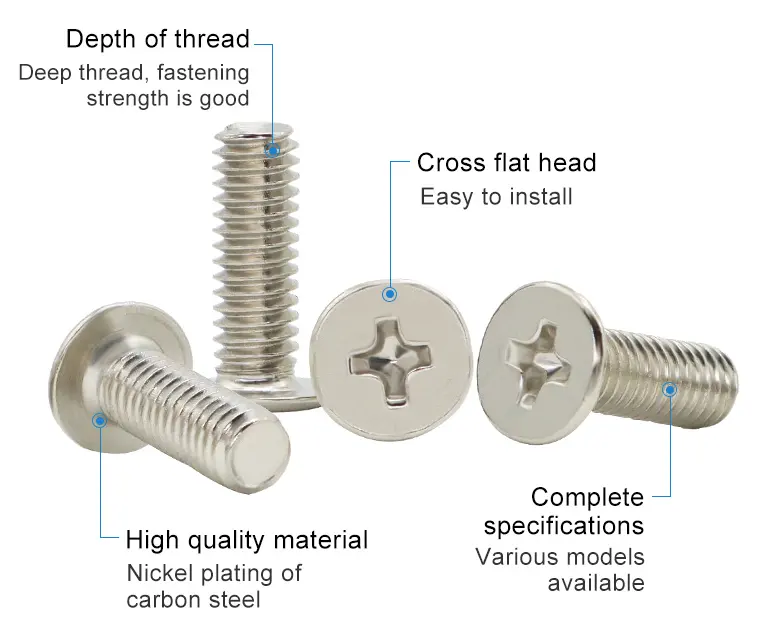

Machine screws are threaded fasteners designed for securing components in machinery, electronics, appliances, and other precision applications. They feature uniform threads along the shank and various head styles (Phillips, slotted, hex, pan, etc.) for specific tooling needs. Manufactured from carbon steel (Grade 4.8/8.8), stainless steel (304/316), or brass/nylon (for non-magnetic/non-conductive use), these screws offer reliable strength and corrosion resistance.

- Material:

- Carbon Steel (zinc-plated, black oxide).

- Stainless Steel (304/316, passivated).

- Non-Metallic: Brass, Nylon (UL94 V-0 compliant for fire resistance).

- Size Range:

- Metric: M1.6–M12 (ISO 14580, ISO 7045).

- Imperial: #0–1/2" (UNC/UNF, ASME B18.6.3).

- Head Styles:

- Phillips, Slotted, Hex, Pan, Flat (countersunk), Round, Torx.

- Thread Type: Full thread, partial thread, or self-tapping (for sheet metal).

- Finish: Zinc plating (RoHS/REACH), passivated (stainless steel), PTFE coating (low friction).

- Standard Carbon Steel/Stainless Steel: 10,000 pieces (common sizes like M3–M6 in stock).

- Non-Metallic/Custom Heads: 5,000 pieces (e.g., brass or Torx-head screws).

Factory Advantages: ISO-certified production, precision threading (tolerance: ±0.02mm), support for micro screws (M1.6–M2.5) and special drive types (e.g., security Torx), with lead times of 7–15 days for standard orders.

- Electronics: Securing PCBs, enclosures, and connectors in computers, servers, and IoT devices.

- Appliances: Assembling motors, hinges, and panels in refrigerators, washing machines, etc.

- Aerospace/Medical: High-precision screws for avionics, surgical tools, and medical devices (316 stainless steel with biocompatible coatings).

- Automotive: Electrical components, interior trim, and small mechanical assemblies.

- Precision Engineering: Tight thread tolerances ensure compatibility with pre-tapped holes in metal/plastic.

- Corrosion Resistance:

- Stainless steel options for high-humidity or chemical environments.

- Nylon screws for non-conductive, anti-corrosive applications (e.g., marine electronics).

- Tool Compatibility: Wide range of drive types (Phillips, Torx) for automated assembly lines.

- Non-Standard Sizes: Micro screws (M1.6), 超长螺丝 (up to 200mm), or metric-imperial hybrid threads.

- Special Coatings: Anti-seize (PTFE), conductive (nickel-plated), or UV-resistant (for outdoor use).

- Head Markings: Laser-engraved part numbers or logos for traceability.

Contact Us

Request a quote for your machine screw requirements! Factory-direct pricing and rapid prototyping for small-batch or bulk orders.

JH Bolt Co., Ltd is a professional manufacturer of different types of bolts with more than 15 years rich manufacturer experience. The factory area is more than 1500 squares with more than hundreds different types ofnevproduction machines. There are more than 50 people who work here for at least 5 years.With quality &customer frst, staffs second, then company, Our products are widely recog-nized and trusted by users all over the world. Proft for the development of communication, We are here for you 12 hours a day, 7 days a week!