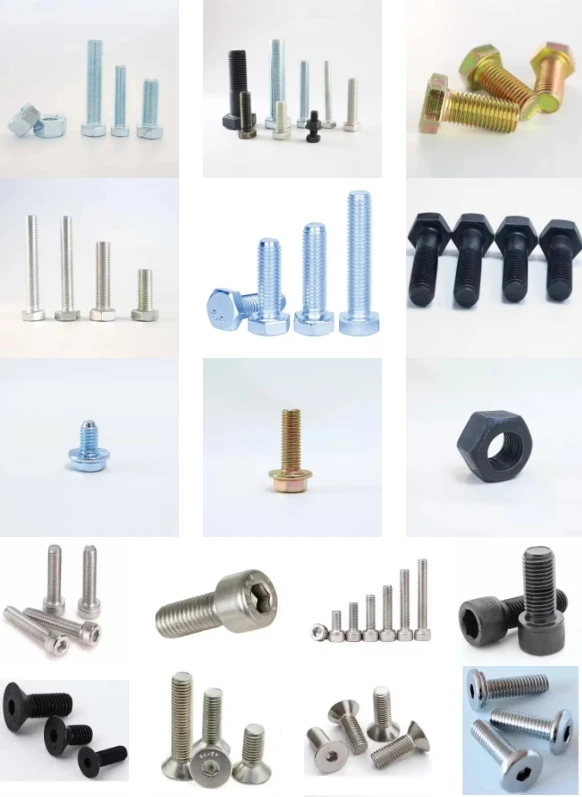

When it comes to securing components in industrial, automotive, or construction projects, high strength stainless steel hexagon socket bolts are one of the most trusted fasteners available. These bolts, known for their durability, strength, and resistance to corrosion, are perfect for heavy-duty applications that require secure fastening in demanding environments. In this article, we will explore the key features, benefits, and applications of high-strength stainless steel hexagon socket bolts.

What Are High Strength Stainless Steel Hexagon Socket Bolts?

High strength stainless steel hexagon socket bolts are fasteners designed with a hexagonal socket head, typically driven by an Allen wrench or hex key. These bolts are made from stainless steel, an alloy that contains chromium to provide enhanced corrosion resistance, strength, and durability. The hexagonal socket allows for efficient torque application, ensuring the bolt remains securely fastened even under high stress.

The “high strength” designation refers to the material’s ability to withstand mechanical stress, heavy loads, and vibrations without breaking, deforming, or loosening. As a result, these bolts are especially valuable in industries where reliability and safety are paramount.

Key Features of High Strength Stainless Steel Hexagon Socket Bolts

- Corrosion Resistance The stainless steel used in these bolts offers superior resistance to rust and corrosion compared to other metals. This makes them ideal for use in environments that are exposed to moisture, chemicals, or extreme weather conditions. The resistance to corrosion ensures the bolts maintain their strength and functionality over long periods.

- High Strength and Durability High-strength stainless steel is designed to resist deformation under heavy loads. These bolts can handle significant mechanical stress and vibration without compromising their integrity, making them an excellent choice for demanding applications.

- Hexagonal Socket Head The hexagonal socket design allows for efficient installation and removal using an Allen wrench or hex key. This design makes it easier to apply higher torque compared to traditional slotted or Phillips head screws, providing a secure and tight fastening.

- Versatility These bolts are available in various sizes and grades to accommodate different applications. From small bolts for light-duty machinery to large bolts for heavy-duty structural components, high-strength stainless steel hexagon socket bolts offer versatility for all types of projects.

Benefits of Using High Strength Stainless Steel Hexagon Socket Bolts

- Increased Reliability When you use high strength stainless steel hexagon socket bolts, you are ensuring that your components will stay securely fastened under demanding conditions. The strength of the material, combined with the secure fit provided by the hexagonal socket, increases the overall reliability of the assembly.

- Enhanced Longevity Stainless steel’s corrosion resistance prevents rust and oxidation, significantly extending the lifespan of the bolt. This is particularly beneficial for applications in harsh environments, such as those exposed to saltwater, chemicals, or extreme temperatures.

- Improved Safety The ability of these bolts to remain securely fastened under stress or vibration ensures that machinery, vehicles, or structural elements remain safe and stable. This makes high-strength stainless steel hexagon socket bolts an essential component in industries where safety is a top priority.

- Aesthetic and Functional Stainless steel bolts offer a polished, clean appearance, making them not only functional but also aesthetically pleasing. This is an important factor in industries like architecture and automotive design, where the appearance of the components is as important as their functionality.

Common Applications of High Strength Stainless Steel Hexagon Socket Bolts

- Construction High strength stainless steel hexagon socket bolts are widely used in construction projects, especially for securing steel beams, structural components, and metal panels. Their strength and corrosion resistance ensure that the bolts perform reliably, even in exposed outdoor environments.

- Automotive Industry In the automotive industry, these bolts are used to secure engine components, chassis parts, and other critical elements of vehicles. The high torque capability of the hexagonal socket head allows for secure fastening in the high-stress environment of an automobile.

- Marine Applications Due to their resistance to corrosion, high-strength stainless steel hexagon socket bolts are frequently used in marine applications. They are ideal for assembling boats, docks, and other marine structures that are constantly exposed to moisture and saltwater.

- Heavy Machinery and Equipment These bolts are commonly used in heavy-duty machinery, such as industrial equipment, cranes, and agricultural machinery. Their ability to withstand vibrations and mechanical stress makes them essential for securing parts in machines that operate under heavy loads.

- Infrastructure Projects For large-scale infrastructure projects, such as bridges, highways, and power plants, high-strength stainless steel hexagon socket bolts are used to secure metal and concrete components. Their ability to perform under extreme conditions ensures that these critical structures remain intact and secure over time.

How to Choose the Right High Strength Stainless Steel Hexagon Socket Bolt

When selecting a high strength stainless steel hexagon socket bolt for your project, it is important to consider the following factors:

- Material Grade Stainless steel bolts come in different grades, such as 304, 316, and 410, each offering varying levels of strength, corrosion resistance, and suitability for different environments. Choose a grade that best matches the demands of your specific application.

- Size and Thread Type Ensure that the size and thread pitch of the bolt match the requirements of your application. This will ensure that the bolt fits properly and can support the required load without failure.

- Load and Stress Requirements Determine the amount of mechanical stress the bolt will be subjected to. High-strength bolts are available in different tensile strength ratings, so choose a bolt with the appropriate strength for your application.

- Environmental Conditions Consider the environment in which the bolt will be used. If the bolt will be exposed to extreme temperatures, chemicals, or outdoor elements, select a bolt with the necessary resistance to corrosion and environmental wear.

Conclusion

High strength stainless steel hexagon socket bolts are an essential fastener solution for industries that require durability, reliability, and high performance. With their superior corrosion resistance, high torque capability, and versatility, these bolts are ideal for heavy-duty applications in construction, automotive, marine, and industrial sectors. By understanding their features and selecting the appropriate size and grade, you can ensure that your assembly projects are secure, safe, and long-lasting.

Whether you’re building a bridge, assembling heavy machinery, or securing critical automotive components, these fasteners provide the strength and durability necessary to withstand the most demanding environments.