Industrial machinery relies heavily on the strength and reliability of its components. Among the key elements ensuring the durability and functionality of these machines are fasteners. One of the most trusted and commonly used fasteners in industrial applications is the high tensile hexagon socket bolt. This article delves into the essential aspects of these bolts, exploring their construction, advantages, and applications.

What Are High Tensile Hexagon Socket Bolts?

A hexagon socket bolt is a type of fastener characterized by its hexagonal socket (or recess) in the head. This design requires a hex key (Allen wrench) for tightening and loosening, offering a flush and aesthetically pleasing finish once installed. When these bolts are described as “high tensile,” it means they are made from materials capable of withstanding significant stress and strain without deforming or failing.

High tensile hexagon socket bolts are manufactured to meet specific strength grades, such as 8.8, 10.9, or 12.9, each indicating the bolt’s tensile strength. The “12.9” grade, for instance, signifies a tensile strength of 1200 MPa and a yield strength of 1080 MPa, making it suitable for demanding industrial applications.

Materials and Coatings

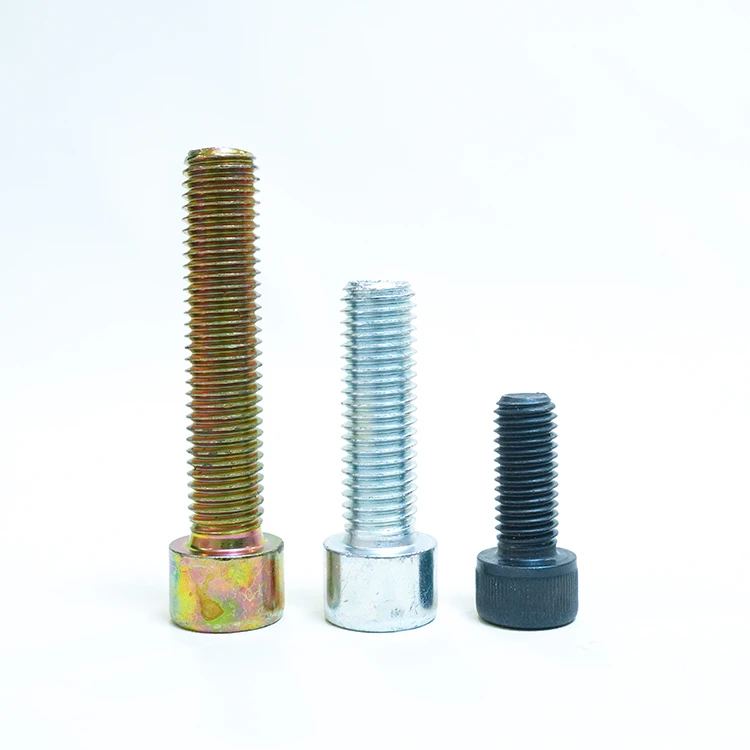

High tensile bolts are typically made from alloy steel or stainless steel to provide superior strength. Alloy steel bolts often undergo heat treatment processes to enhance their tensile properties, while stainless steel options offer additional resistance to corrosion.

Coatings are another critical feature. Common coatings include:

- Zinc Plating: Provides corrosion resistance, ideal for indoor applications.

- Hot-Dip Galvanizing: Offers enhanced protection against rust, making it suitable for outdoor and marine environments.

- Black Oxide Coating: Adds a sleek appearance and mild corrosion resistance, often used in applications where aesthetics matter.

Key Features and Benefits

- Strength and Durability

High tensile hexagon socket bolts can withstand heavy loads and high-pressure environments, making them ideal for industrial machinery subjected to intense forces. - Compact Design

The hexagonal socket design allows for a compact head, enabling installation in tight spaces where traditional bolts may not fit. - Precision Engineering

These bolts are manufactured with precision to meet strict dimensional tolerances, ensuring consistent performance and reliable fastening. - Ease of Use

The use of a hex key allows for easy installation and removal, even in confined or hard-to-reach areas. - Enhanced Safety

Their superior strength reduces the risk of failure under stress, ensuring safety and minimizing downtime in industrial operations.

Applications of High Tensile Hexagon Socket Bolts

These bolts are essential in various industries, particularly in applications requiring high strength and durability. Some common uses include:

- Heavy Machinery: Securing components in equipment such as cranes, excavators, and industrial presses.

- Automotive Sector: Used in engine assemblies, gearboxes, and other high-performance automotive parts.

- Construction: Fastening structural components and heavy frameworks.

- Aerospace: Critical in aircraft manufacturing for their strength-to-weight ratio and reliability.

- Oil and Gas: Essential for securing equipment in high-pressure and corrosive environments.

Installation Tips

To maximize the performance and lifespan of high tensile hexagon socket bolts, proper installation is crucial. Here are some key tips:

- Use the Correct Tools

Always use the appropriate size hex key to prevent stripping the socket. - Ensure Proper Torque

Over-tightening or under-tightening can compromise the bolt’s performance. Use a torque wrench to achieve the recommended torque levels. - Inspect Threads

Before installation, ensure that both the bolt and the receiving threads are clean and undamaged. - Apply Lubrication

For bolts exposed to harsh environments, consider applying a thread lubricant to ease installation and reduce the risk of galling. - Periodic Maintenance

Regularly inspect bolts in critical applications for signs of wear or damage, and replace them as necessary to maintain safety.

Common Misconceptions

- “High tensile bolts are indestructible.”

While these bolts are exceptionally strong, they are not immune to failure if used improperly. Always select the right grade and size for the application. - “Coatings are just for looks.”

Coatings play a vital role in extending the lifespan of bolts by protecting them from corrosion and wear. - “All hexagon socket bolts are the same.”

The strength, material, and coating vary significantly between bolts. Always check the specifications to ensure compatibility with your needs.

Why Choose High Tensile Hexagon Socket Bolts?

Investing in high-quality fasteners like high tensile hexagon socket bolts offers numerous long-term benefits. They reduce the risk of mechanical failures, improve safety, and ensure the reliability of industrial machinery. By selecting the right bolt for your application, you can enhance the efficiency and longevity of your equipment.

Conclusion

High tensile hexagon socket bolts are an indispensable component in industrial machinery, offering unparalleled strength, durability, and reliability. Understanding their features, benefits, and proper use can help industries make informed decisions and achieve optimal performance. Whether you’re securing heavy machinery or assembling precision equipment, these bolts provide a dependable solution for even the most demanding applications.