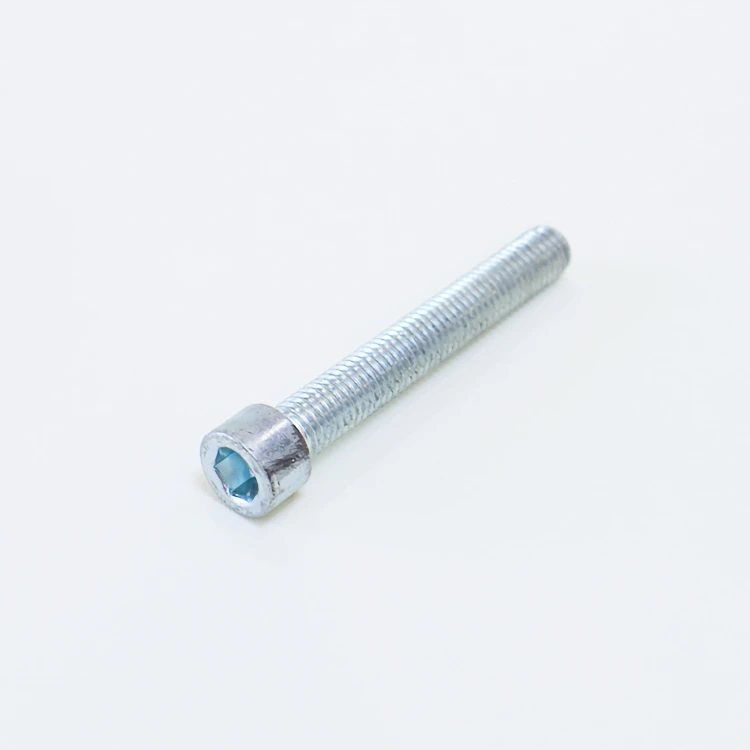

DIN 912 grade 8.8 hexagonal socket head bolts, also commonly known as Allen bolts, are indispensable components in numerous industrial and manufacturing applications. These bolts are recognized for their robustness, reliability, and ease of use. This article explores the key features, applications, and benefits of these high-strength fasteners, providing a detailed understanding of their role in various sectors.

Understanding DIN 912 Standard

The DIN 912 standard specifies the requirements for hexagonal socket head bolts, which include dimensions, mechanical properties, and material specifications. These bolts feature a cylindrical head with a hexagonal recess that accommodates an Allen wrench or hex key for installation and removal. This design provides a secure and efficient means of tightening, ensuring strong and reliable fastening.

Key Characteristics

- Material and Grade:

- Grade 8.8: This grade indicates that the bolt is made from medium carbon steel, quenched and tempered, providing a tensile strength of 800 MPa and a yield strength of 640 MPa. These properties make the bolts suitable for applications requiring high strength and durability.

- Head Design:

- Hexagonal Socket: The hexagonal recess in the head allows for high torque transmission, reducing the risk of slippage and providing a secure fit. This design is ideal for applications where space is limited, and a traditional wrench cannot be used.

- Threading:

- Metric Coarse and Fine Threads: Available in both coarse and fine threading, these bolts offer flexibility for different applications, ensuring maximum holding power and resistance to vibration.

Applications

DIN 912 grade 8.8 hexagonal socket head bolts are utilized across a wide range of industries, including:

- Automotive: Essential for assembling engine components, suspension systems, and other critical parts that require high-strength fasteners.

- Machinery and Equipment: Used in the construction and assembly of industrial machinery, ensuring secure and durable connections that can withstand significant stress and strain.

- Aerospace: Employed in the manufacturing of aircraft components where high strength and reliability are paramount.

- Construction: Used in structural applications where high-strength fasteners are required to ensure safety and integrity.

- Electronics: Ideal for securing components in electronic devices where a compact and reliable fastening solution is necessary.

Advantages

- High Strength: Grade 8.8 bolts provide excellent tensile and yield strength, making them suitable for heavy-duty applications.

- Compact Design: The hexagonal socket head design allows for use in confined spaces where traditional bolt heads would not fit.

- Corrosion Resistance: Often available with various coatings or in stainless steel, these bolts can withstand corrosive environments, extending their service life.

- Ease of Installation: The use of an Allen wrench simplifies the installation and removal process, making it quick and efficient.

- Versatility: Suitable for a wide range of applications, from automotive to aerospace, providing a reliable fastening solution for diverse needs.

Installation Tips

- Proper Tools: Ensure the correct size Allen wrench or hex key is used to prevent damage to the bolt head and to achieve the proper torque.

- Torque Specifications: Follow the recommended torque values to avoid over-tightening, which could damage the bolt or the assembled components.

- Clean Threads: Ensure that both the bolt and the receiving threads are clean and free of debris to facilitate smooth installation and prevent cross-threading.

Conclusion

DIN 912 grade 8.8 hexagonal socket head bolts are a versatile and reliable choice for various industrial applications. Their high strength, compact design, and ease of use make them a preferred fastener in many sectors, including automotive, aerospace, and construction. Understanding their characteristics and proper installation techniques will ensure optimal performance and longevity in any application. Whether you are assembling machinery, constructing a building, or manufacturing automotive components, these bolts provide a secure and durable solution for your fastening needs.